Square Bottle Capping Machine

Square Bottle Capping Machine

Looking for a Square Bottle Capping Machine in India? Our company is a leading supplier offering reliable and efficient capping solutions tailored to Indian market demands. With state-of-the-art design and precision engineering, our machines handle square bottles of various sizes with ease, ensuring optimal productivity. Whether you’re in Delhi, Mumbai, Bangalore, or any part of India, we deliver high-quality machines with comprehensive after-sales support. Contact us today for the best Square Bottle Capping Machine price in India and elevate your production efficiency.

Square Bottle Capping Machine

Square Bottle Capping Machine: Full Description and Technical Specifications

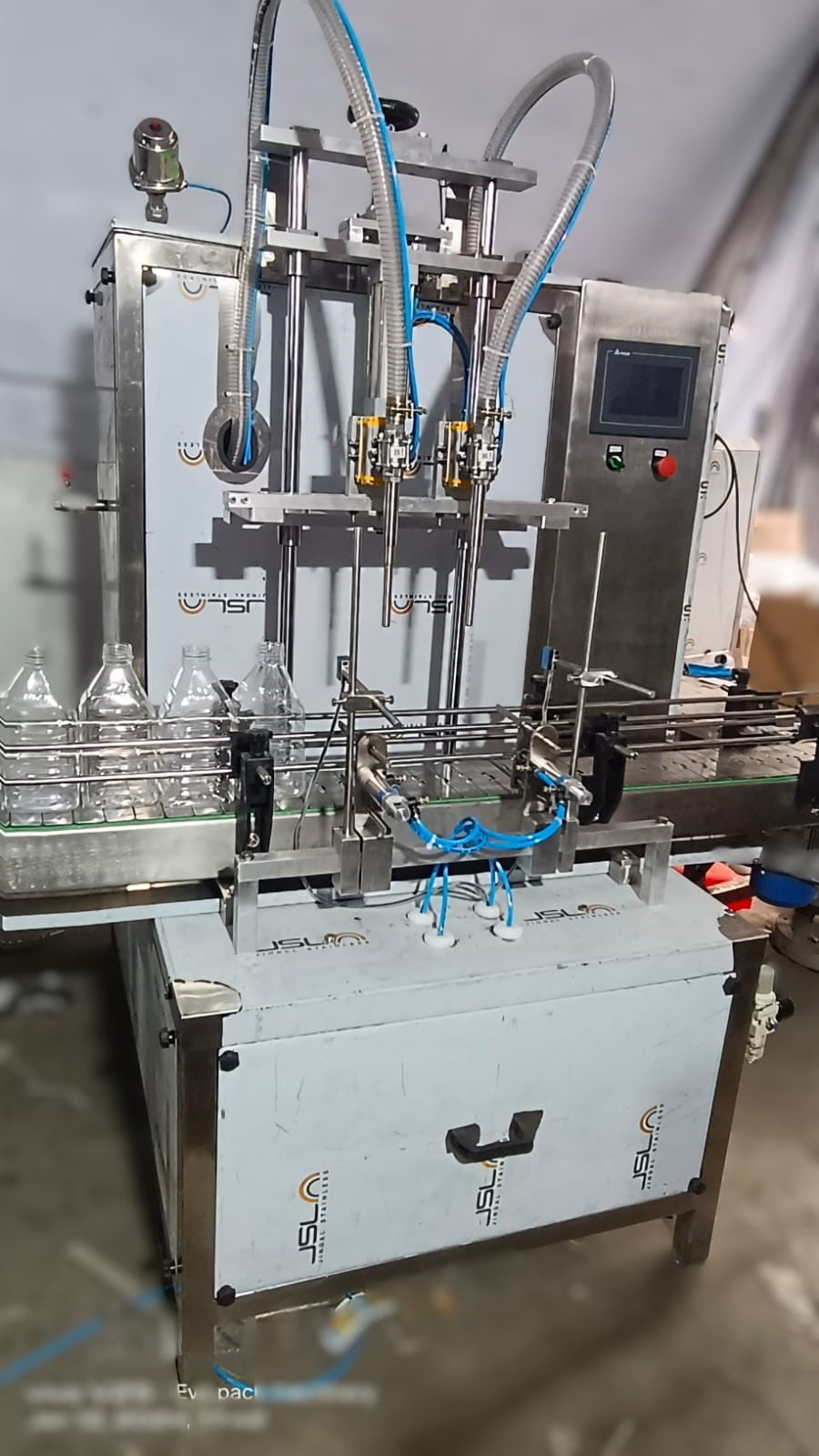

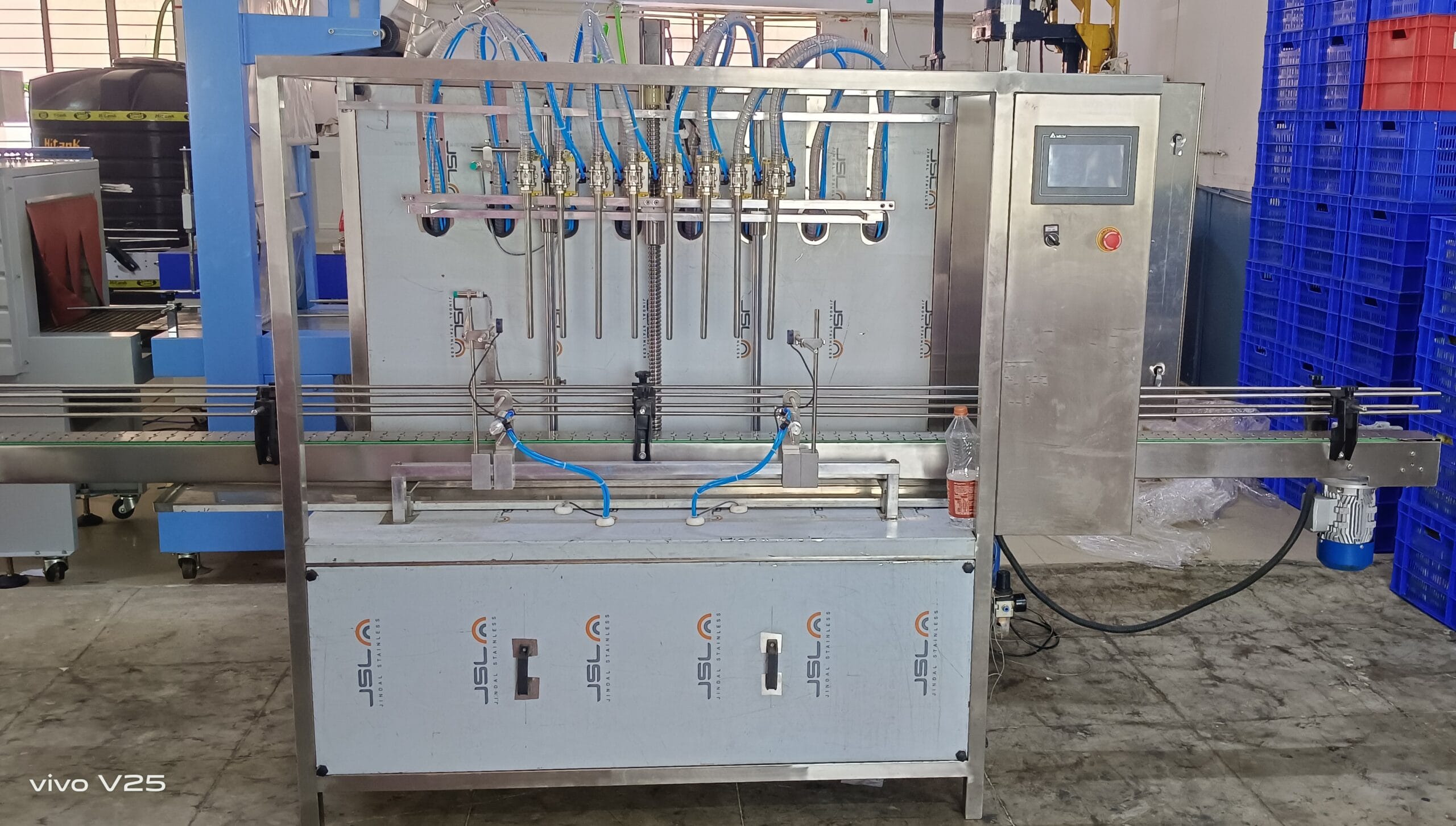

The Square Bottle Capping Machine is an advanced solution designed for precise and efficient capping of square-shaped bottles across various industries such as pharmaceuticals, cosmetics, food, and chemicals. This Square Bottle Capping Machine ensures consistent torque application, preventing under-tightening or over-tightening. Constructed with robust stainless steel, it features an adjustable capping head, a conveyor system for smooth bottle movement, and a PLC-based control system for precision operation. With quick changeover capabilities and user-friendly controls, this Square Bottle Capping Machine is ideal for high-speed production lines, ensuring efficiency, accuracy, and durability.

The Square Bottle Capping Machine is designed with quick changeover capabilities, making it convenient to switch between different bottle sizes and cap types. This feature is particularly beneficial for industries that deal with various product lines. Moreover, the adjustable capping head ensures uniform torque application, preventing issues like over-tightening or under-tightening, which can compromise the seal’s integrity or damage the bottle.

Future Advancements

The future of the Square Bottle Capping Machine lies in the integration of smart technologies. Upcoming innovations may include IoT-enabled monitoring systems for real-time data tracking, predictive maintenance capabilities to minimise downtime, and enhanced automation for even greater efficiency. These advancements will cater to the growing demand for higher productivity and sustainability in manufacturing processes.

Technical Specifications: Square Bottle Capping Machine

- Capping Speed: Up to 30 bottles per minute

- Bottle Size: Handles square bottles of 50 ml to 1000 ml

- Cap Types: Screw caps, flip-tops, or other custom closures

- Material: Stainless steel construction

- Control System: Push Butten

- Power Supply: 220vt. Single Phase.

- Features: Adjustable capping head, auto cap feeding, torque control, quick changeover, and integration with existing production lines.

Features: Square Bottle Capping Machine

- Adjustable capping head for precise torque application

- Automatic cap feeder for seamless operation

- Quick changeover for different bottle and cap sizes

- Integration capability with existing production lines

- Compact design for space efficiency

- Compliance with industry hygiene and safety standards

Applications of the Square Bottle Capping Machine

The Square Bottle Capping Machine is versatile and caters to a range of industries:

- Pharmaceuticals: Ensures airtight capping for medicines and syrups, maintaining product efficacy and compliance with regulatory standards.

- Cosmetics: Provides precise capping for bottles containing lotions, shampoos, and creams, enhancing product aesthetics and consumer trust.

- Food and Beverages: Secures bottles containing oils, sauces, and drinks, preserving freshness and preventing contamination.

- Chemical Industry: Offers reliable capping for chemicals and cleaning products, ensuring safety during transport and storage.

Why Choose Our Square Bottle Capping Machines?

- Precision and Efficiency: Designed to provide consistent and accurate capping, ensuring product quality and integrity.

- Durable Construction: Made with high-grade stainless steel for long-lasting performance and compliance with hygiene standards.

- Customisable Features: Easily adaptable to various bottle sizes and cap types, with quick changeover capabilities.

- Advanced Technology: PLC-based control system for precision, with options for integration into existing production lines.

- Customer Support: Comprehensive after-sales service, including installation, training, and maintenance, ensuring seamless operation.