Share Tweet Pin Mail SMS Automatic Four Head Milk Filling Machine 26 November 2024 TRENDING Automatic Four Milk Filling Machine-EPM40 23 November …

Automatic Four Head Milk Filling Machine

Automatic Four Head Milk Filling Machine

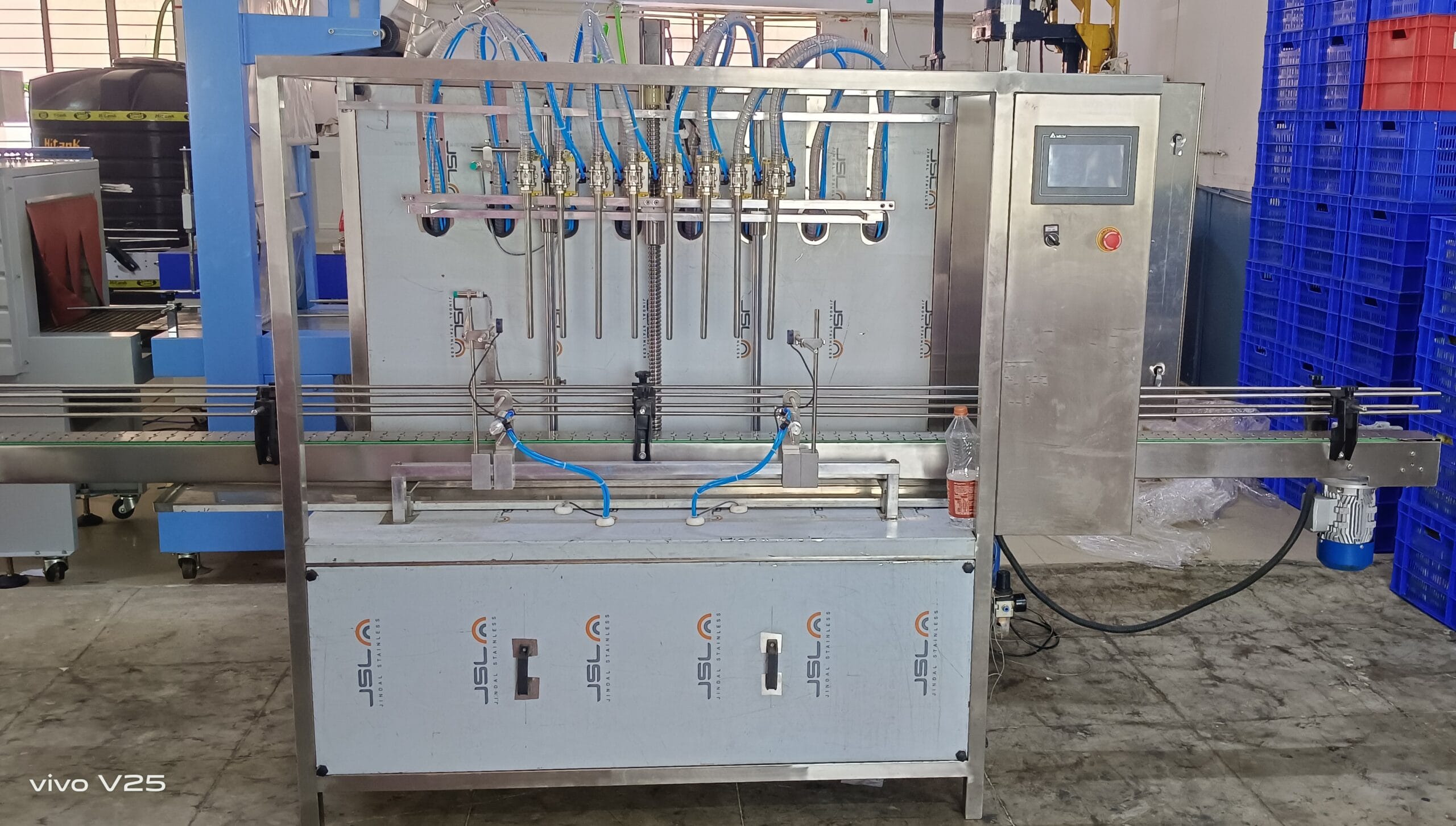

The Automatic Four Head Milk Filling Machine is a state-of-the-art packaging solution designed to streamline the filling process for liquid milk in various container types, ensuring speed, precision, and hygiene. Engineered for industries requiring high-volume production, such as dairy processing plants and beverage manufacturers, this machine is tailored to meet the stringent quality standards of modern-day production. Its robust design, advanced technology, and operational flexibility make it an indispensable asset for businesses aiming to optimise efficiency and maintain consistent product quality.

This machine features four independent filling heads, each equipped with high-precision nozzles for accurate and uniform milk dispensing. It employs a volumetric or flow meter-based filling mechanism, ensuring minimal wastage and consistent fill levels across all containers. The machine is capable of handling various container types, such as plastic bottles, glass bottles, and tetra packs, making it versatile for a range of packaging needs.

Constructed from high-grade stainless steel, the machine offers excellent durability and corrosion resistance, essential for the dairy industry's hygiene standards. The modular design ensures ease of cleaning and maintenance, while its compact footprint allows it to be integrated seamlessly into existing production lines. Its user-friendly interface, powered by a PLC (Programmable Logic Controller) system with an intuitive HMI (Human-Machine Interface), enables operators to monitor and control the filling process efficiently.

The Automatic Four Head Milk Filling Machine is equipped with advanced safety features, including emergency stop buttons, protective enclosures, and safety interlocks, ensuring operator safety during operation. Additionally, its ability to handle high-speed operations while maintaining accuracy makes it ideal for large-scale production environments, ensuring businesses can meet market demands without compromising quality.

- Filling Speed: Up to 60-100 bottles per minute (dependent on bottle size and milk viscosity)

- Filling Volume: Adjustable from 200ml to 2 litres

- Filling Mechanism: Servo and Gear Pump

- Material: Stainless steel (304/316L for contact parts)

- Bottle Types: Plastic bottles, glass bottles.

- Control System: PLC with HMI touch screen

- Power Requirement: 220V/380V, 50Hz/60Hz

- Compressed Air Requirement: 0.6-0.8 MPa

- Machine Dimensions: Customisable to fit production line

- Weight: Approx. 600 kg

- Additional Features:

- No-drip filling nozzles to prevent spillage

- Automatic container detection and alignment

- Quick changeover for different container sizes

- CIP (Clean-in-Place) compatibility

- Advanced safety mechanisms (emergency stop buttons, interlocks)

- Dairy Industry: Filling fresh milk, flavoured milk, and buttermilk into bottles or tetra packs.

- Beverage Industry: Packaging liquid dairy-based drinks and non-dairy milk alternatives.

- Food Industry: Filling liquid ingredients, such as cream and yoghurt.

- Pharmaceuticals: Handling other liquid medicines with similar viscosity.

Share Tweet Pin Mail SMS Automatic Dry Syrup Powder Filling Machine 11 October 2024 TRENDING Automatic Dry Syrup Powder Filling Machine-EPMDF60 11 …

Share Tweet Pin Mail SMS Automatic Palm Oil Filling Machine Automatic Palm Oil Filling Machine The Automatic Palm Oil Filling Machine in …

Share Tweet Pin Mail SMS Automatic Round Bottle Sticker Labeling Machine Automatic Round Bottle Sticker Labeling Machine The Automatic Round Bottle Sticker …

Automatic Soda Bottle Capping Machine-EPM30

coconut oil automatic filling machine-EPMFL40

Related

Thank you for Connecting

May I Help You

Any questions related to Automatic Four Milk Filling Machine-EPM40?

WhatsApp Us

🟢 Online | Privacy policy