Share Tweet Pin Mail SMS Automatic Four Head Milk Filling Machine 26 November 2024 TRENDING Automatic Four Milk Filling Machine-EPM40 23 November …

Automatic Multi Head Capping Machine

Automatic Multi Head Capping Machine

Automatic Multi Head Capping Machine in India In India, the demand for automatic multi head capping machines is on the rise, driven by the expanding pharmaceutical, food and beverage, and cosmetic industries. Indian manufacturers and suppliers provide cutting-edge capping machines designed to meet the specific needs of local and international clients. These machines ensure efficiency, accuracy, and durability, making them ideal for both small-scale operations and large industrial plants. With features like automatic cap feeding, precise torque control, and easy maintenance, these machines enhance productivity and maintain consistent quality. The adoption of automatic multi-head capping machines in India is set to rise, driving innovation and excellence in the packaging industry.Automatic Multi Head Capping Machine Supplier in India India hosts a robust network of suppliers offering automatic multi-head capping machines. These suppliers provide advanced solutions with the latest technology to ensure precise and efficient capping processes. Known for their commitment to quality and customer satisfaction, Indian suppliers deliver reliable, durable machines that adhere to international standards. They cater to various industries, offering customized options for different production scales and packaging needs. Indian suppliers are renowned for their support and service, making them a preferred choice for businesses in the packaging industry.Automatic Multi Head Capping Machine Manufacturer in India India is home to leading manufacturers of automatic multi-head capping machines. These manufacturers use advanced technology and high-quality materials to produce efficient and reliable capping solutions. Their machines are designed to meet the specific needs of various industries, ensuring precision, durability, and high performance. Indian manufacturers are known for their innovation and adherence to international standards, making them a trusted source for capping machines. With a focus on customer satisfaction and after-sales support, they continue to drive excellence in the packaging machinery sector.

Automatic Multi Head Capping Machine

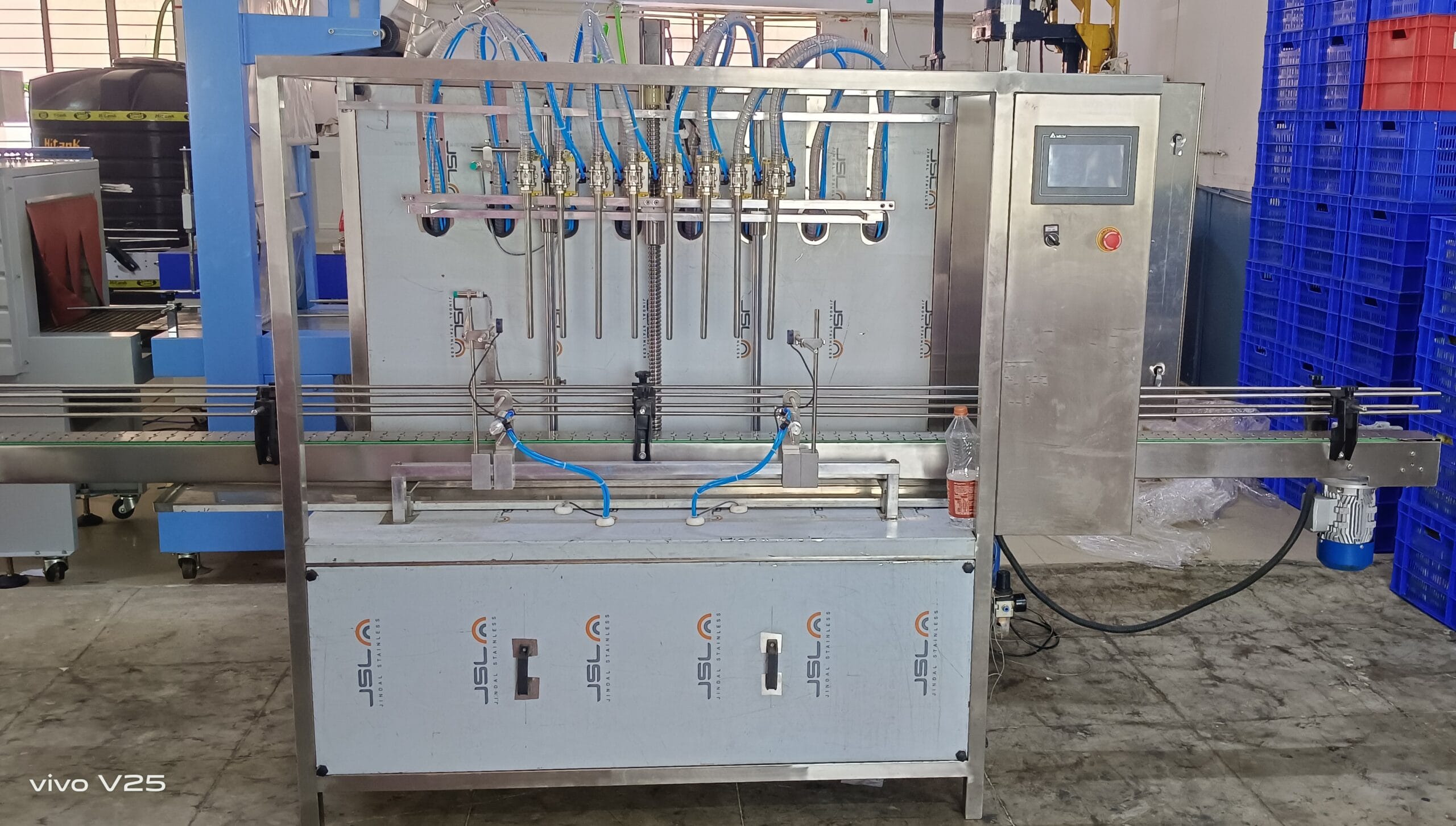

The Automatic Multi Head Capping Machine from Eva Pack Machinery is an advanced solution designed for efficient and reliable capping of bottles and containers across various industries, including pharmaceuticals, food and beverages, cosmetics, and chemicals. Engineered for high-speed operations, this machine ensures consistent torque application, providing a secure seal for a wide range of cap types and sizes. With its robust construction and precision-engineered components, the multi-head capping machine is built to deliver exceptional performance and durability.

The Automatic Multi Head Capping Machine features a fully automated system that incorporates a sophisticated PLC (Programmable Logic Controller) with a touch screen HMI (Human-Machine Interface) for easy operation and monitoring. It is equipped with multiple capping heads that work simultaneously to increase throughput and maintain a high level of accuracy. The automatic cap feeder system ensures a continuous supply of caps, minimising downtime and maximising productivity.

Constructed from high-grade stainless steel, the machine offers superior resistance to corrosion and is designed to meet stringent hygiene standards, making it ideal for use in cleanroom environments. Its flexible design allows for quick and easy changeovers between different bottle sizes and cap types, providing versatility for manufacturers with diverse product lines.

The Automatic Multi Head Capping Machine also includes advanced safety features such as emergency stop buttons, safety interlocks, and protective enclosures to ensure operator safety during operation. Its compact footprint makes it suitable for integration into existing production lines without requiring excessive space.

- Capping Speed: Up to 80 bottles per minute (depending on bottle and cap size)

- Cap Diameter: 18mm to 100mm

- Bottle Height: 50mm to 350mm

- Control System: Push Button.

- Power Supply: 220V/380V, 50Hz/60Hz

- Compressed Air Requirement: 0.5-0.8MPa

- Material: Stainless steel (304/316L for contact parts)

- Dimensions: Customizable based on production line requirements

- Weight: Approx. 600 kg

- Additional Features: Automatic cap sorting and feeding system, adjustable torque control, quick changeover for different cap sizes, safety interlocks, and emergency stop button.

- High Efficiency: Capable of capping a large number of bottles per minute, significantly boosting production rates.

- Precision Capping: Utilises advanced torque control to ensure consistent and secure sealing.

- Versatility: Accommodates a wide range of bottle sizes and cap types, including screw caps, snap-on caps, and press-on caps.

- User-Friendly Interface: Intuitive touchscreen controls for easy operation and quick adjustments.

- Durability: Constructed from high-quality stainless steel, ensuring long-lasting performance and resistance to corrosion.

- Safety: Equipped with safety interlocks and emergency stop functions to protect operators and prevent accidents.

- Easy Maintenance: Designed for easy cleaning and maintenance, with quick-disconnect parts for hassle-free upkeep.

- Customizable: Options to customize based on specific production needs and container requirements.

- Pharmaceutical Industry: Capping bottles containing medicines, syrups, and other pharmaceutical products.

- Food and Beverage Industry: Sealing containers with sauces, juices, oils, and other consumables.

- Cosmetic Industry: Capping bottles with perfumes, lotions, and other beauty products.

- Chemical Industry: Securing containers with chemicals and industrial liquids.

The future of automatic multi head capping machines is bright, with technological advancements continually enhancing their capabilities. Future iterations may incorporate artificial intelligence for predictive maintenance and process optimisation, as well as IoT connectivity for real-time monitoring and data analysis. These developments will further improve efficiency, reduce downtime, and increase production flexibility. As industries increasingly embrace automation, the demand for high-performance capping machines is expected to grow, driving innovation and setting new standards for quality and efficiency in the packaging industry.

Share Tweet Pin Mail SMS Automatic Dry Syrup Powder Filling Machine 11 October 2024 TRENDING Automatic Dry Syrup Powder Filling Machine-EPMDF60 11 …

Share Tweet Pin Mail SMS Automatic Palm Oil Filling Machine Automatic Palm Oil Filling Machine The Automatic Palm Oil Filling Machine in …

Share Tweet Pin Mail SMS Automatic Round Bottle Sticker Labeling Machine Automatic Round Bottle Sticker Labeling Machine The Automatic Round Bottle Sticker …

Share Tweet Pin Mail SMS Ayurvedic Powder Filling Machine

Share Tweet Pin Mail SMS Automatic Multi Head Capping Machine 8 August 2024 TRENDING Automatic Multi Head Capping Machine EPM80 8 August …

Share Tweet Pin Mail SMS Automatic Single Head Dry Syrup Powder Filling Machine Automatic Single Head Dry Syrup Powder Filling Machine Automatic …

Share Tweet Pin Mail SMS Automatic Lubricant Oil Filling 22 July 2024 TRENDING Automatic Lubricant Oil Filling Machine 22 July 2024 Water …

Share Tweet Pin Mail SMS Water Bottle Filling Machine We are a prominent supplier of Water Bottle Filling Machines in India. Our …

Share Tweet Pin Mail SMS Automatic Vegetable Oil Filling Machine in India India is at the forefront of manufacturing advanced automatic vegetable …

People also ask :

An automatic capping machine is a device used in manufacturing and packaging industries to secure caps onto bottles and containers efficiently and consistently. These machines are designed to automate the capping process, improving production speed and ensuring uniformity in the packaging.

The working principle of a capping machine involves several steps to ensure that caps are securely and efficiently placed onto bottles or containers. The process can vary slightly depending on the type of capping machine, but generally, it follows these key steps:

An ROPP (Roll-On Pilfer Proof) capping machine is a specialized type of capping machine designed to apply tamper-evident aluminum caps onto bottles, commonly used in the beverage, pharmaceutical, and cosmetics industries. ROPP caps are popular because they provide a secure seal and include a pilfer-proof feature that indicates if the cap has been opened.

A crown capping machine is used to apply crown caps onto bottles, typically glass bottles, in the beverage industry. Crown caps, also known as crown corks, are the metal caps with a corrugated edge that are commonly used to seal carbonated beverages like beer and soft drinks. These machines are essential for ensuring a secure and airtight seal, which helps maintain the beverage’s carbonation and freshness.

Capping machines come in various types, each designed to handle specific capping requirements and production environments. Here are the main types of capping machines used in different industries:

1. Screw Capping Machines

- Automatic Screw Cappers: These machines automatically place and screw caps onto containers. They are used in high-volume production lines and can handle various cap sizes and styles, including plastic and metal caps.

- Semi-Automatic Screw Cappers: Require some manual intervention for positioning caps but automate the screwing process, suitable for medium production volumes.

- Inline Screw Cappers: These cappers operate in line with other packaging machines, applying caps as bottles move along a conveyor belt.

- Rotary Screw Cappers: Feature multiple heads that rotate to apply caps simultaneously, increasing speed and efficiency in high-volume operations.

2. ROPP (Roll-On Pilfer Proof) Capping Machines

- Used to apply tamper-evident aluminum caps, especially for products like wine, spirits, and pharmaceuticals.

- Rollers form threads on the aluminum caps as they are applied to the bottle, ensuring a secure and tamper-evident seal.

Capping machines are essential in various industries for securing caps onto containers, ensuring product integrity, safety, and shelf life. Here are some of the key applications of capping machines across different sectors:

### 1. **Beverage Industry**

– **Carbonated Drinks**: Used for sealing bottles of soda, beer, and other carbonated beverages to maintain carbonation and prevent leaks.

– **Juices and Water**: Ensure airtight seals on bottles of water, juices, and other non-carbonated drinks, preserving freshness and preventing contamination.

– **Spirits and Wine**: ROPP capping machines and corkers are used for sealing wine bottles and spirits, providing tamper-evident seals.

### 2. **Food Industry**

– **Sauces and Condiments**: Ensure a secure seal on bottles and jars of sauces, ketchup, mustard, and other condiments, preserving flavour and extending shelf life.

– **Dairy Products**: Used to cap milk and cream bottles, ensuring product freshness and safety.

– **Jams and Preserves**: Vacuum capping machines are used for creating airtight seals on jars of jams and preserves.

### 3. **Pharmaceutical Industry**

– **Medicines**: Securely cap bottles of liquid medications, ensuring sterility and preventing contamination.

– **Nutraceuticals**: Cap bottles of vitamins and dietary supplements, maintaining product integrity and compliance with safety standards.

### 4. **Cosmetics and Personal Care**

– **Perfumes and Fragrances**: Ensure a tight seal on bottles of perfumes and fragrances, preventing evaporation and maintaining product quality.

– **Lotions and Creams**: Cap jars and bottles of lotions, creams, and other personal care products to prevent leaks and contamination.

### 5. **Chemical Industry**

– **Cleaning Products**: Securely cap bottles of household and industrial cleaning products, ensuring safety and preventing spills.

– **Industrial Chemicals**: Provide tamper-evident seals on containers of industrial chemicals and solvents, ensuring safety and compliance with regulations.

### 6. **Automotive Industry**

– **Lubricants and Oils**: Cap bottles and cans of automotive oils, lubricants, and fluids, ensuring product safety and preventing leaks.

### 7. **Agricultural Industry**

– **Pesticides and Fertilizers**: Seal containers of liquid and powdered agricultural products, ensuring safety and preventing contamination.

### Benefits of Using Capping Machines

– **Product Integrity**: Ensures a secure seal that preserves product quality and extends shelf life.

– **Efficiency**: Automates the capping process, increasing production speed and reducing labour costs.

– **Consistency**: Provides uniform sealing, reducing the risk of product spoilage or leakage.

– **Safety and Compliance**: Ensures products are sealed according to industry standards and regulations, enhancing consumer safety.

### Considerations for Application

– **Cap and Bottle Compatibility**: Ensure the capping machine is compatible with the cap and bottle types used in the production process.

– **Production Volume**: Select a machine that matches the production scale, with automatic machines suited for high-volume operations and semi-automatic machines for smaller production runs.

– **Integration**: Consider how the capping machine fits into the overall production line, including compatibility with fillers, labelers, and other equipment.

Capping machines play a critical role in maintaining product quality and safety across a wide range of industries, making them an essential component of modern manufacturing and packaging operations.

Related

Thank you for Connecting

May I Help You

Any questions related to Automatic Multi Head Capping Machine EPM80?

WhatsApp Us

🟢 Online | Privacy policy