Share Tweet Pin Mail SMS Automatic Four Head Milk Filling Machine 26 November 2024 TRENDING Automatic Four Milk Filling Machine-EPM40 23 November …

Automatic Mustard Oil Filling Machine

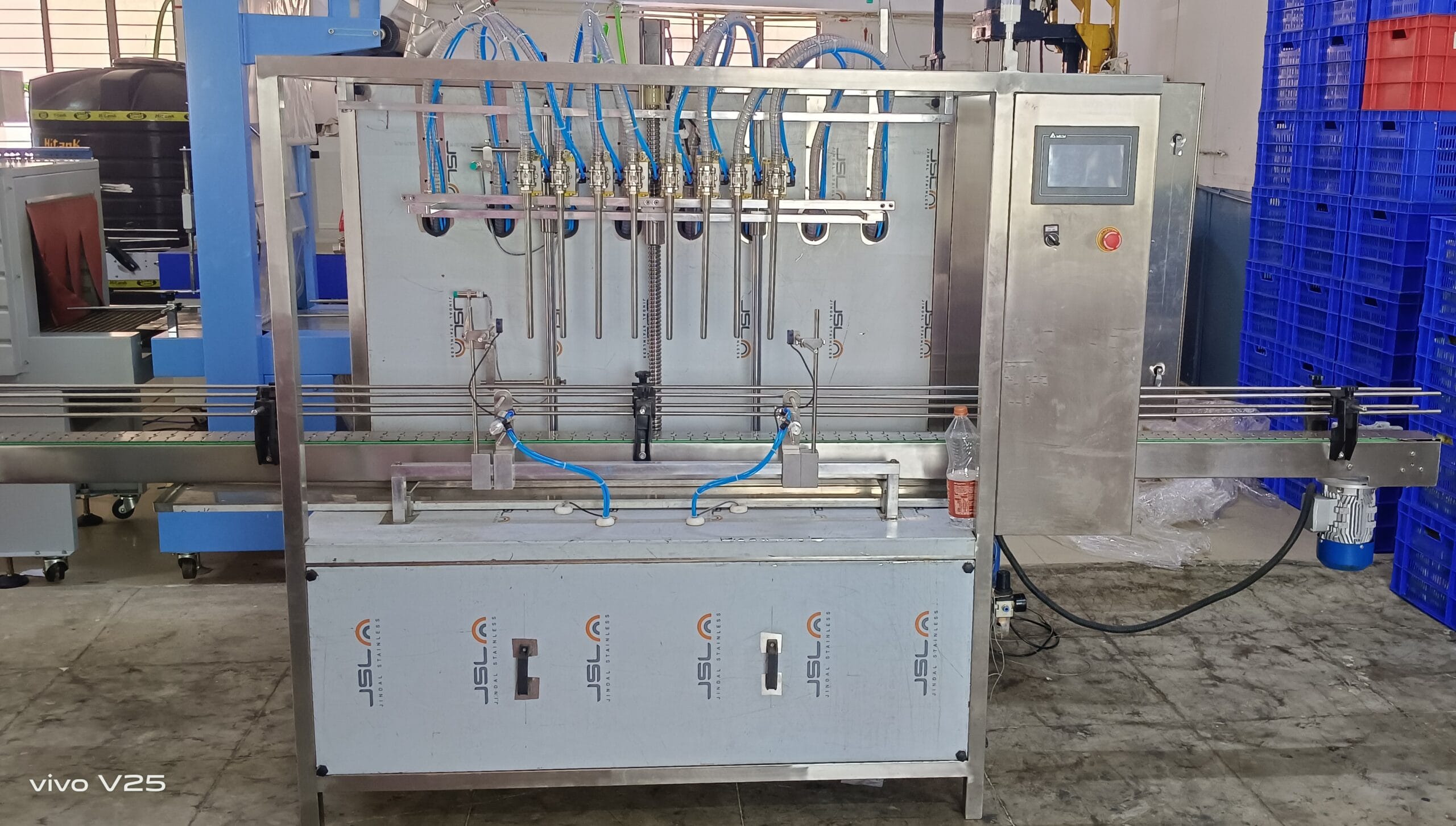

Revolutionizing Oil Production: The Automatic Mustard Oil Filling Machine

In the bustling world of manufacturing, efficiency is key. As industries strive to meet consumer demands while maintaining quality standards, innovations continue to drive progress. One such innovation making waves in the realm of oil production is the Automatic Mustard Oil Filling Machine. This groundbreaking technology is transforming the way mustard oil is filled, packaged, and delivered to consumers worldwide.

The Evolution of Oil Filling Technology:

Gone are the days of manual labor and time-consuming processes. With the advent of automatic filling machines, the landscape of oil production has undergone a significant transformation. The Automatic Mustard Oil Filling Machine represents the pinnacle of this evolution, offering unparalleled efficiency and precision.

Streamlining Production with Advanced Automation:

At the heart of the Automatic Mustard Oil Filling Machine lies advanced automation technology. This state-of-the-art equipment is designed to streamline the entire filling process, from container placement to sealing. By eliminating the need for manual intervention, manufacturers can significantly increase their output while minimizing errors.

Efficiency Redefined:

One of the most significant advantages of the Automatic Mustard Oil Filling Machine is its unparalleled efficiency. With the ability to fill a large number of bottles or containers in a fraction of the time it takes manually, manufacturers can boost their productivity exponentially. This means meeting growing consumer demands without compromising on quality or consistency.

Precision Engineering for Perfect Fillings:

Precision is paramount when it comes to oil filling, and the Automatic Mustard Oil Filling Machine delivers on this front with utmost accuracy. Equipped with advanced sensors and controls, this cutting-edge equipment ensures that each container is filled to the exact specifications, minimizing wastage and maximizing yield.

Enhancing Quality Control Standards:

Maintaining consistent quality is a top priority for any manufacturer, and the Automatic Mustard Oil Filling Machine plays a crucial role in upholding these standards. With built-in quality control mechanisms, including leak detection and volume verification, manufacturers can rest assured that every product that leaves the production line meets the highest quality requirements.

Versatility to Suit Diverse Needs.

Flexibility is key in today’s dynamic market, and the Automatic Mustard Oil Filling Machine offers unmatched versatility to adapt to diverse production requirements. Whether filling different container sizes or adjusting filling volumes, this adaptable equipment can easily cater to varying needs, providing manufacturers with the agility they need to stay ahead of the competition.

Cost-Effective Solutions for Long-Term Success.

Investing in the Automatic Mustard Oil Filling Machine isn’t just about boosting productivity; it’s also a strategic move towards long-term cost savings. By minimizing labor costs, reducing wastage, and optimizing production efficiency, manufacturers can enjoy significant returns on their investment, ensuring sustainable growth and success in the competitive marketplace.

The maximum filling capacity of an automatic mustard oil filling machine can vary depending on the specific model. The search results provide different capacities for these machines:

– One source mentions a capacity of 1200 to 1800 bottles per hour[1].

– Another source specifies a capacity of 20 bottles per minute[2].

– A different source indicates a capacity of 1200 to 2400 bottles per hour[3].

– Lastly, there is a mention of a capacity of 20 bottles per hour[4].

Therefore, the maximum filling capacity of an automatic mustard oil filling machine can range from 20 bottles per minute to 1800 bottles per hour, depending on the specific model and manufacturer.

The maintenance requirements for an automatic mustard oil filling machine typically include regular cleaning, lubrication of moving parts, inspection of seals and gaskets, calibration of filling volumes, and periodic checks of electrical components. It is essential to follow the manufacturer’s maintenance guidelines to ensure the machine operates efficiently and maintains product quality. Regular maintenance helps prevent breakdowns, ensures accurate filling volumes, and prolongs the machine’s lifespan.

Based on the information provided in the search results, the key differences between a fully automatic and semi-automatic mustard oil filling machine are:

1. **Automation Level**:

– **Fully Automatic Mustard Oil Filling Machine**: These machines are highly automated and require minimal human intervention. They are designed for high-speed filling operations and are suitable for medium-to-large-scale production.

– **Semi-Automatic Mustard Oil Filling Machine**: These machines require some manual intervention during the filling process. An operator is responsible for initiating and monitoring the filling process. They are ideal for low-to-medium-volume production runs.

2. **Filling Accuracy**:

– **Fully Automatic Mustard Oil Filling Machine**: These machines provide precise control over the filling process, ensuring consistent and accurate filling volumes for each container. This level of control is crucial for cost control and quality assurance.

– **Semi-Automatic Mustard Oil Filling Machine**: These machines may have limitations in accurately controlling the amount of mustard oil input into each container. Manual handling can lead to variations in filling volumes, potentially causing product overflow, leakage, or underfilling.

3. **Production Efficiency**:

– **Fully Automatic Mustard Oil Filling Machine**: These machines offer high production efficiency, with some models achieving over 98% overall machine efficiency. They are suitable for large-scale production and can handle high-speed filling operations.

– **Semi-Automatic Mustard Oil Filling Machine**: While semi-automatic machines can improve filling efficiency compared to manual devices, they are not as efficient as fully automatic machines. They are designed for smaller production runs.

4. **Suitability for Production Scale**:

– **Fully Automatic Mustard Oil Filling Machine**: These machines are designed for medium to large-scale production. They are capable of handling high-speed filling operations and are ideal for businesses looking to increase production efficiency and output.

– **Semi-Automatic Mustard Oil Filling Machine**: These machines are suitable for small to medium production runs, such as in family workshops or businesses with lower production volumes.

In summary, the key differences lie in the level of automation, filling accuracy, production efficiency, and suitability for different production scales, with fully automatic mustard oil filling machines being more advanced and suitable for larger-scale operations compared to semi-automatic machines.

Share Tweet Pin Mail SMS Automatic Dry Syrup Powder Filling Machine 11 October 2024 TRENDING Automatic Dry Syrup Powder Filling Machine-EPMDF60 11 …

Share Tweet Pin Mail SMS Automatic Palm Oil Filling Machine Automatic Palm Oil Filling Machine The Automatic Palm Oil Filling Machine in …

Share Tweet Pin Mail SMS Automatic Round Bottle Sticker Labeling Machine Automatic Round Bottle Sticker Labeling Machine The Automatic Round Bottle Sticker …

Share Tweet Pin Mail SMS Ayurvedic Powder Filling Machine

Share Tweet Pin Mail SMS Automatic Multi Head Capping Machine 8 August 2024 TRENDING Automatic Multi Head Capping Machine EPM80 8 August …

Related

Thank you for Connecting

May I Help You

Any questions related to Automatic Mustard Oil Filling Machine-EPMFL40?

WhatsApp Us

🟢 Online | Privacy policy