Liquid Detergent Filling Machine

Liquid Detergent Filling Machine

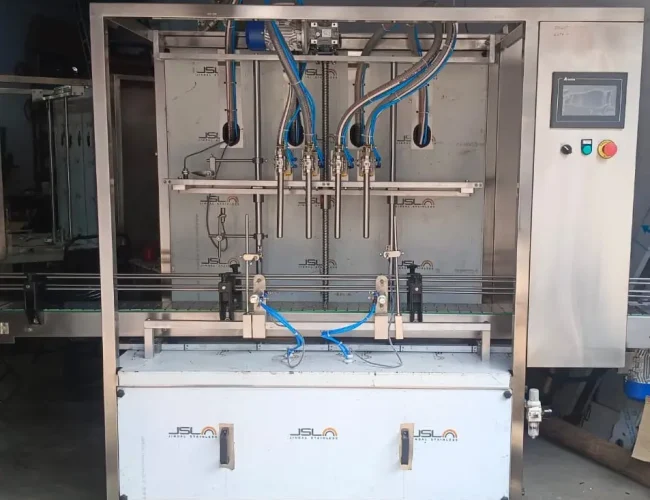

As a leading Fully Liquid Detergent Filling Machine Line Manufacturer in India, we specialize in providing cutting-edge solutions that optimize the efficiency and accuracy of liquid detergent packaging processes. Our fully automated liquid detergent filling machine lines are meticulously designed to cater to the specific needs of the detergent manufacturing industry, ensuring seamless operation and precise fill volumes. We offer competitive Fully Liquid Detergent Filling Machine Price in India, ensuring accessibility to businesses of all sizes without compromising on quality. Whether you're looking to invest in a Fully Liquid Detergent Filling Machine for sale or seeking a reliable Fully Liquid Detergent Filling Machine supplier in India, our commitment to excellence and innovation guarantees top-tier equipment and exceptional service.Our Fully Liquid Detergent Filling Machines in India feature state-of-the-art technology such as PLC controls, touchscreen interfaces, and high-precision filling mechanisms, ensuring accurate measurement and minimal product wastage. Built from durable materials and compliant with stringent hygiene standards, our machines are designed for reliability and longevity in demanding production environments.Investing in our Fully Liquid Detergent Filling Machine lines means investing in efficiency and consistency for your production processes. Whether for small-scale operations or large-scale manufacturing, our machines are adaptable to various bottle sizes and production volumes, ensuring a secure and hygienic packaging process. Explore our range of advanced solutions tailored to optimize your liquid detergent filling processes and enhance your business capabilities with reliable and innovative filling solutions..

Liquid Detergent Filling Machine

Description

Liquid detergent filling machines are advanced industrial equipment designed to precisely fill liquid detergents into containers of various sizes. These machines streamline the packaging process, ensuring efficiency, accuracy, and consistency in product filling.

Specification

Capacity and Speed:

The liquid detergent filling machine boasts a capacity of [up to 1200 Bottles ] per hour, making it suitable for both small-scale and large-scale production lines. With its high-speed filling mechanism, it can efficiently fill a wide range of container sizes without compromising accuracy.

Material Compatibility:

Constructed with high-grade stainless steel, the liquid detergent filling machine is compatible with a variety of liquid detergent formulations, including viscous and corrosive substances. Its corrosion-resistant properties ensure longevity and durability even in demanding industrial environments.

Filling Precision:

Equipped with advanced technology, this filling machine offers exceptional filling precision, minimizing product waste and ensuring every container is filled to the desired level. Its adjustable filling parameters allow for precise control over the filling process, accommodating different types of liquid detergents.

Operation:

Featuring user-friendly controls and intuitive interfaces, the liquid detergent filling machine is easy to operate and maintain. Operators can quickly adjust settings, monitor production metrics, and troubleshoot potential issues, minimizing downtime and maximizing productivity.

Versatility and Flexibility:

The machine’s versatile design enables it to adapt to various container shapes, sizes, and materials, including bottles, jars, and pouches. Its flexible configuration options allow for seamless integration into existing production lines, offering scalability and customization according to specific manufacturing requirements.

Features :

Automatic Filling System:

The liquid detergent filling machine is equipped with an automatic filling system that precisely dispenses the desired amount of detergent into containers, eliminating the need for manual intervention and ensuring consistency in product packaging.

Multi-Head Filling Nozzles:

With multi-head filling nozzles, the machine can fill multiple containers simultaneously, significantly enhancing throughput and efficiency in high-volume production environments.

Integrated Quality Control Mechanisms:

Built-in quality control mechanisms monitor the filling process in real-time, detecting and rectifying any deviations to maintain product integrity and adherence to quality standards.

Sanitary Design:

The machine’s sanitary design features smooth surfaces and easy-to-clean components, facilitating thorough sanitation procedures to prevent cross-contamination and ensure product purity.

Modular Configuration:

Its modular configuration allows for easy customization and expansion, enabling manufacturers to adapt to evolving production demands and incorporate additional functionalities as needed.

Conclusion:

In summary, the liquid detergent filling machine combines precision, reliability, and versatility to optimize the packaging process for liquid detergents. Its advanced features and robust construction make it an indispensable asset for manufacturers seeking to enhance efficiency and quality in detergent production.

This comprehensive specification and description outline the machine’s capabilities, features, and benefits, positioning it as a leading solution in the liquid detergent packaging industry.

Thank you for Connecting

May I Help You

Any questions related to Liquid Detergent Filling Machine?

WhatsApp Us

🟢 Online | Privacy policy

Contact Us:

Request a quote from Eva Pack Machinery today for the best packaging solution

Get Best Quote and Details From ' Eva Pack Machinery'