Share Tweet Pin Mail SMS Automatic Four Head Milk Filling Machine 26 November 2024 TRENDING Automatic Four Milk Filling Machine-EPM40 23 November …

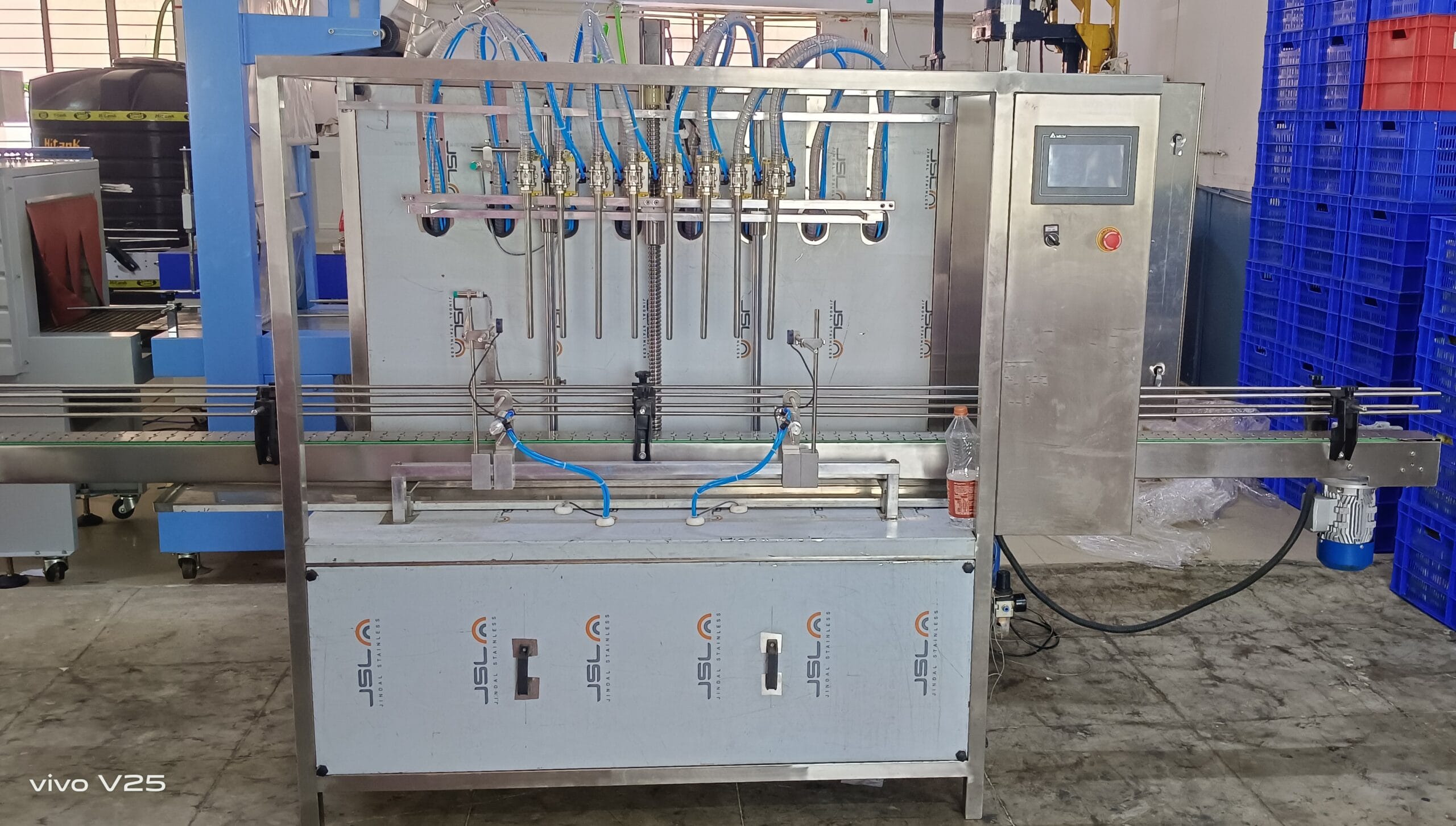

Water Bottle Filling Machine

Water Bottle Filling Machine in India India's water bottling industry is experiencing significant growth, driven by increasing consumer demand for clean and safe drinking water. Water bottle filling machines in India are designed to meet this demand, offering advanced features that ensure precision, hygiene, and efficiency. Indian manufacturers and suppliers provide a range of machines that cater to various production scales, from small businesses to large industrial operations. These machines are built to handle the diverse requirements of the Indian market, ensuring reliable and high-quality bottling processes.Water Bottle Filling Machine Supplier in India India boasts a robust network of suppliers for water bottle filling machines, delivering state-of-the-art solutions to the beverage industry. These suppliers offer machines equipped with the latest technology, ensuring precise and efficient filling processes. They provide customised solutions to meet the specific needs of their clients, whether for small-scale operations or large industrial plants. Known for their commitment to quality and customer satisfaction, Indian suppliers deliver durable and reliable machines that adhere to international standards.Water Bottle Filling Machine in India The growing demand for bottled water in India has increased the adoption of water bottle-filling machines. These machines are essential for ensuring the bottling process's efficiency, accuracy, and hygiene. Indian manufacturers and suppliers offer a wide range of machines that cater to different production needs, from small businesses to large-scale operations. With the focus on quality and innovation, water bottle-filling machines in India are set to drive the future of the beverage industry, providing safe and reliable bottled water to consumers.

Description:

A water bottle filling machine is an advanced piece of equipment designed to streamline the process of filling water into bottles. These machines are essential for the beverage industry, ensuring high efficiency, precision, and hygiene. They come equipped with a conveyor system, multiple filling nozzles, a capping mechanism, and an intuitive control panel. These machines can handle various bottle sizes and shapes, filling a wide range of volumes accurately and consistently. High-end models also integrate bottle rinsing and capping functions, offering a complete bottling solution.

Technical Specification:

- Filling Range: 200ml to 2000ml (customisable)

- Filling Speed: Up to 24 bottles per minute (depending on bottle size and water type)

- Accuracy: ±0.2%

- Nozzle Type: Multiple nozzles ( 4, 6, etc.), anti-drip design

- Control System: Push Button Human Machine Interface

- Power Supply: 220V/380V, 50Hz/60Hz

- Compressed Air Requirement: 0.4-0.6MPa

- Material: Stainless steel (304 for contact parts)

- Dimensions: Customized based on production line requirements

- Weight: Approx. 800 kg

- Additional Features: Manual bottle rinsing, filling, and capping; bottle feeding and discharge system; emergency stop button.

Features:

- High Efficiency: Capable of filling a large number of bottles per minute, significantly boosting production capacity.

- Precision Filling: Utilises advanced sensors and PLC control for accurate filling, minimising waste and ensuring uniformity.

- Versatility: Adjustable to accommodate various bottle sizes and shapes, suitable for different water types.

- User-Friendly Interface: Intuitive touch screen controls for easy operation and quick adjustments.

- Durability: Constructed from high-grade stainless steel, ensuring longevity and resistance to corrosion.

- Safety: Equipped with safety interlocks and emergency stop functions to protect operators and prevent accidents.

- Comprehensive Solution: Includes rinsing, filling, and capping functions for an all-in-one bottling solution.

- Easy Maintenance: Designed for easy cleaning and maintenance, with quick-disconnect parts for hassle-free upkeep.

Applications:

- Beverage Industry: Filling bottles with mineral water, spring water, and purified water.

- Food Industry: Bottling flavoured waters and non-carbonated beverages.

- Healthcare: Filling medicinal waters and dietary supplements.

- Cosmetic Industry: Bottling beauty and skincare waters.

- Hospitality Sector: Providing bottled water for hotels, restaurants, and events.

Share Tweet Pin Mail SMS Automatic Dry Syrup Powder Filling Machine 11 October 2024 TRENDING Automatic Dry Syrup Powder Filling Machine-EPMDF60 11 …

Share Tweet Pin Mail SMS Automatic Palm Oil Filling Machine Automatic Palm Oil Filling Machine The Automatic Palm Oil Filling Machine in …

Share Tweet Pin Mail SMS Automatic Round Bottle Sticker Labeling Machine Automatic Round Bottle Sticker Labeling Machine The Automatic Round Bottle Sticker …

Share Tweet Pin Mail SMS Ayurvedic Powder Filling Machine

Share Tweet Pin Mail SMS Automatic Multi Head Capping Machine 8 August 2024 TRENDING Automatic Multi Head Capping Machine EPM80 8 August …

Related

Thank you for Connecting

May I Help You

Any questions related to Water Bottle Filling Machine?

WhatsApp Us

🟢 Online | Privacy policy